SEMI E157

Specification for Module Process Tracking

Front-end process equipment in 300mm semiconductor factories use recipes to control wafer processing. The latest generation of process advancements requires equipment suppliers to present a more granular view of the process execution as defined in a new industry standard.

The SEMI E157 Module Process Tracking standard provides a common paradigm for equipment to report data associated with recipe step execution without requiring equipment to change existing recipe definitions. E157 helps both device makers and users of equipment data to collect information from specific process program (Module Recipe Execution) steps. Using this standard reduces the amount of data that needs to be collected from wafer process equipment by providing very specific data during critical processing steps.

Factories Need More of the Right Data to Increase Efficiency

One problem factories face is that events and data available to track the execution of a recipe on an individual substrate or batch are inconsistent from equipment to equipment and, in some cases, insufficient to meet the needs of the device maker. Because of that, factories have experienced increased costs due to customization for each equipment type they integrate into the factory. In addition, there was previously insufficient context data (e.g. substrate ID, job ID, recipe ID) and insufficient events to support critical equipment data collection. Furthermore, trace data collection cannot be started at the optimum time (e.g., when a certain recipe step starts). The result was factories could not collect important event data properly.

SEMI developed the E157 standard to resolve those problems. E157 defines a standard equipment capability to report recipe processing related data to the factory system. E157 allows modeling of chamber sub-processes, and those individual actions can now be traced within a given module.

The collection of process data during recipe execution is important to today's semiconductor factories in order to optimize equipment processes, finished product quality, yield, and overall factory performance.The E157 specification enables the process data to be associated with the recipe steps. This association makes it much easier for the factories to analyze the process data.

Standard events that document recipe execution guarantee the availability of the context information. The context data may include such items as:

- Identification of process job

- Equipment recipe

- Affected substrates

The reporting capability provides a record of start and/or end of processing, with granularity to the recipe step level.

Reporting of these events must be process module-specific to support the reporting of process module-specific data parameters.

Standardizing Process Event Reporting

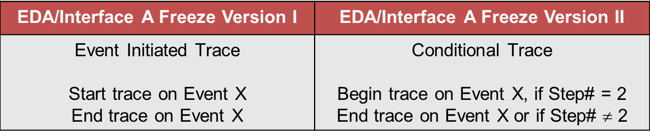

EDA/Interface A data is expected to be collected at high frequencies in trace data reports, which can add a lot of stress to tools and factory systems. To minimize this stress, this type of tracing can be limited to those times when the relevant data is available. This type of tracing, known as a "conditional trace" is new to EDA/Interface A Freeze Version II.

In Freeze Version I, data gathering had to be explicitly started and then stopped, or started and then run for a specific period.In Freeze Version II, traces can be defined to start when a condition is TRUE, then continue either until a condition changes, or after a specified period. Specific traces can be triggered using state models, reducing the total volume of data gathered. Equipment suppliers can define state models in the metadata, and factories can require the E157 specification state model for use in conditional traces.

Before the SEMI E157 specification was approved, data collection for chamber-specific recipe execution was available but not standardized. Implementation details, consistency and quality varied from equipment to equipment and from equipment supplier to equipment supplier. Solutions did not always provide the desired recipe step resolution or data. The solution was SEMI E157, which standardizes process event reporting and makes it far more intuitive.

The E157 standard allows the factories to focus their data collection using conditional data trace for key process periods, enabling short duration, high data rate burst mode. This reduces overall data needs from the equipment by enabling focused data analysis. In addition, E157 standardizes the process data to provide consistency and predictability across all equipment types, which reduces production costs and allows the factories to know what to expect.

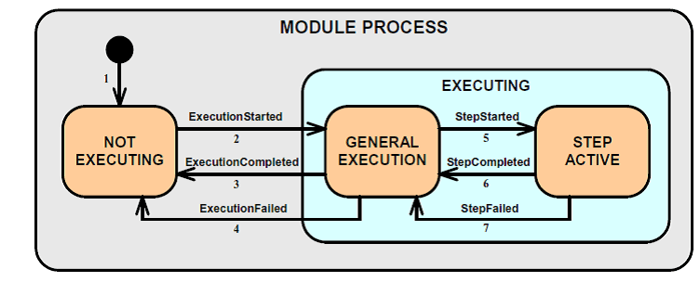

The Module Process Tracking state model captures all the recipe steps, as defined by the equipment supplier, from processing start to processing stop. Recipe step boundaries are ideal for trace start and trace stop events. E157 also standardizes context data, such as JobID, recipe settings, etc. Equipment suppliers can add their tool-specific data. The Module Process state model is applied to each process chamber, and it enables the collection of chamber-specific data.

Description of SEMI E157 Standard Parameters

| Parameter | Description | Data Type |

| RCID | Recipe Component Identifier - the identifier of the recipe component specifying the instructions for the activity in the associated process module (may be master recipe or a sub-recipe) | String |

| RecID | Recipe Identifier - The identifier of the master recipe executing on the equipment | String |

| ModuleID | Module Identifier - The identifier of the equipment module in which the module process is taking place (in EDA, the Locator of the Module) | String |

| SubstrateID or SubstrateIDList | Substrate Identifier(List) - ID of the substrate(s) processed by this module process activity. Parameter is a list if multiple substrates can be processed together. | String or List of Strings |

| ProcessJobID or ProcessJobIDList | The identifier(s) of the SEMI E40 ProcessJob(s) responsible for the recipe execution related to the Module (if E40 is supported). Parameter is a list if multiple ProcessJobs can execute in the process module at one time (rarely the case). | String or List of Strings |

| RecipeParameters | The recipe parameter settings applied to the executing recipe component to alter this instance of execution. This is not necessarily the E40 ProcessJob recipe parameter list. | List of Structures |

| StepID | Identifier of the recipe step definition within the recipe. The StepID is unique within the scope of the associated recipe. | String |

| StepCount | A value that represents the number of recipe steps executed. This counter shall have the value of 1 for the first step executed for the recipe component and is incremented for each successive step as it begins execution. | Integer |

Other Major SEMI EDA Standards

Download the complete Cimetrix white paper on the SEMI EDA Standards.