Cimetrix Sapience® Smart Factory Platform

A cloud native platform

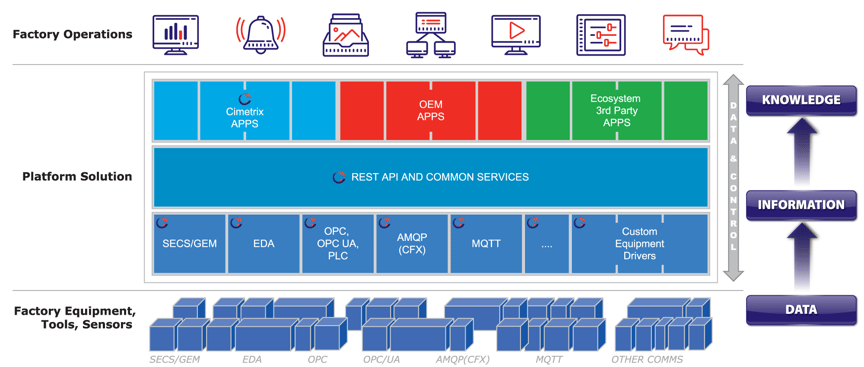

Cimetrix Sapience is a distributed platform for managing high-performance data pipelines from electronics equipment. Ideal for streaming analytics, machine learning, and artificial intelligence applications requiring data directly from the production equipment.

REQUEST A SAPIENCE SANDBOX TRIAL

OR DOWNLOAD THE SAPIENCE DATA SHEET

CLOUD NATIVE

Deploy how you see fit. Cloud, Hybrid, Bare Metal.

FAST CONNECTION TO EQUIPMENT

Access any equipment with GEM, EDA, OPC, MQTT, Kafka, or other protocols.

BUILT WITH OPEN APIs

Prevents expensive vendor lock-in and proprietary consulting service traps with a platform designed for modern AI/ML pipelines.

TRUSTED BY OEMs

TRUSTED BY THE ELECTRONICS INDUSTRY

Thousands of equipment operate today with our connectivity and control products onboard. Utilize a trusted name in the front and back-end electronics space to implement your next-generation solutions.

APPLICATION SCALABILITY

APPLICATION SCALABILITY

Deploy your production applications using all the benefits of a cloud-native architecture (Scale, Redundancy, Ephemeral Work Loads, CI/CD).

HIGH THROUGHPUT

HIGH THROUGHPUT

Gather data at any rate the equipment can deliver.

ACCESS NEW TALENT

ACCESS NEW TALENT

Put new programming resources to work immediately without having to learn your deep industry knowledge.

EQUIPMENT DATA AT SCALE

Build Machine Learning and AI Solutions that rely on tool data using a cloud-native Kubernetes Architecture.

Built on Kubernetes and optimized for cloud computing, the Sapience Platform is essential for developing enterprise applications requiring data streamed directly from the equipment. The Sapience Rest APIs abstract away the intricate details of tool communications and provides your application developers a mechanism to innovate using all the latest tools in the fastest means possible.

REQUEST A SAPIENCE SANDBOX TRIAL