The Software Framework for Equipment Automation

Cimetrix CIMControlFramework - Semiconductor Equipment Control

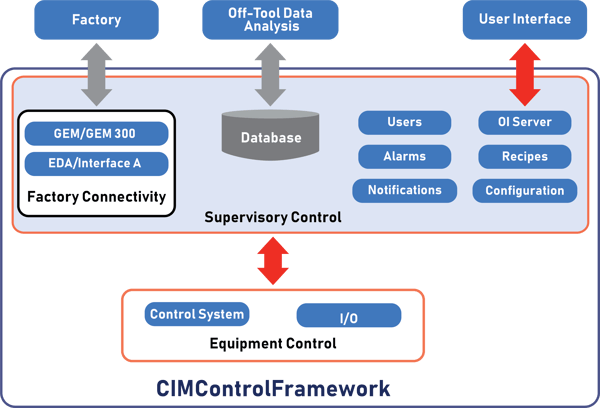

Cimetrix CIMControlFramework™ (CCF) is an equipment automation framework based on Microsoft .NET technology. The CCF equipment control solution allows OEMs to meet the supervisory control, material handling, platform and process control and factory automation requirements of the factories. Equipment suppliers can leverage framework components through configuration and extension, or customize when unique requirements exist.

Cimetrix CIMControlFramework™ (CCF) is an equipment automation framework based on Microsoft .NET technology. The CCF equipment control solution allows OEMs to meet the supervisory control, material handling, platform and process control and factory automation requirements of the factories. Equipment suppliers can leverage framework components through configuration and extension, or customize when unique requirements exist.

The CIMControlFramework product is supported and maintained with upgrades, improvements, and performance enhancements.

We offer CCF Services

The Cimetrix CCF (CIMControlFramework) Services team will help you build a strategic plan to implement CCF as quickly and time effectively as possible.

Our CCF Services team will work side-by-side with you to implement your CCF-based equipment control solution, or simply train you on how to do the project yourself. We work with your team the entire way. We train you on the portions of the projects assigned to us so that when you are ready, you can own the project. This includes decision making, milestones and implementation.

Our customers [were] demanding high-speed, dependable information from tool suppliers in order to improve yield, productivity and reliability. Axcelis and Cimetrix developed software for our Integra RS tool using CIMControlFramework to deliver optimum data collection, storage, management and analysis. Process and equipment engineers now have more information accessible to them for accurate monitoring and troubleshooting, saving them time and improving performance of the toolset.

Bill Bintz, Senior Vice President of Marketing, Axcelis Technologies, Inc.

What Makes CIMControlFramework Unique?

- Modern, open architecture

- Well defined interfaces allows customization and/or replacement CCF components based on business needs

- Ease transition from current equipment control system to CCF, in an agile, iterative fashion, greatly reducing risk

- New components can be easily added and take advantage of existing services

- CCF GUIs can be developed using either WPF or WinForms

- SECS/GEM, GEM300 and EDA standards are built-in

- Cimetrix keeps product current with standards at all times

- These standards apply to front-end and are commonly being adopted by back-end equipment manufacturers

- You get the complete Source Code

- Provides ultimate control when trying to optimize equipment performance

- Equipment Manufacturers can better leverage their expertise to add value to their process module and platform

- Robust system diagnostics

- Logging is built-in and troubleshoots problems remotely

Key features include supervisory control and factory automation

Supervisory Control

CIMControlFramework provides a complete and configurable supervisory control solution.

- User Interface (E95) -

- A complete set of common user interface screens is included (e.g. job management, configuration, recipe management, process data viewer, etc.).

- Recipe Management

- Scheduler

- Data Analysis

- Configuration Management

Factory Automation

CIMControlFramework leverages our industry-leading factory automation solutions: CIMConnect™ for SECS/GEM, CIM300™ for GEM300, and CIMPortal™ Plus for EDA/Interface A.

- Substrate Tracking (E90)

- Equipment Performance Tracking/EPT (E116)

- Control Jobs (E94) and Process Jobs (E40)

- Carrier Management (E87)

- Process Execution Tracking (E157)

Other

- Simulation

- Enable testing when equipment is not available.

- System Diagnostics

- Fully working samples

- Vacuum and atmospheric wafer samples

- Continuous flow sample