Background

Several years ago, I was working with a client implementing EDA who wanted to collect data at higher than typical rates using the EDA trace data collection feature (essentially periodic data polling). The typical EDA data collection rate I was used to was 10 Hz, with a couple of clients implementing 20 Hz or even 40 Hz. This client, however, wanted to collect data at about 1000 Hz. This was a lot faster than we normally could accomplish, especially since the software timers and clock functionality in Windows are really designed for about 15 ms intervals. Therefore, the normal means of implementing the data collection was not going to work very well.

With a little creative thinking, I came up with a solution. Instead of using trace data collection, I decided to try event data collection. Every 1 second, I triggered an event notification and provided 1000 data samples with the event that had been collected at 1 ms intervals and stored. The 1000 samples were presented to the EDA client as an array of data, which EDA supports directly, and this solution worked very well. I also found that this approach used surprisingly few resources to implement and transmit, largely because the data is so compact. It was also very reliable.

Although this event with array data solution worked in this very specific situation, there were a few drawbacks. First of all, the client could not choose the data collection interval. Normally with trace data collection the client chooses the data collection rate to meet the needs of a specific data collection application. Secondly, the client receiving the data had to know what the data meant. The client application software had to be programmed to understand that each value in the 1000 sample array represented data collected every 1 ms. Finally, I could not use the trace start trigger and stop trigger to automatically enable and disable the reporting of the data collected. Normally, trace data collection can be started and stopped automatically to collect data between specific equipment events, which is a nice feature to focus data collection between specific processing steps or other meaningful activities.

EDA Freeze 3

A couple of years ago, the SEMI North America DDA (Diagnostics and Data Acquisition) task force, which I co-lead, decided to begin work on the next version of the EDA standards suite, commonly referred to as EDA Freeze 3. As part of this work, I raised an issue that I wanted our task force to address. That is, I wanted to be able to collect data using the EDA standard at higher frequencies than the typical 10 Hz available using today’s trace data collection. In particular, I wanted to leverage what I had learned using the event data array solution to report data collection at 1000 Hz and faster, and make this an integral part of the EDA standard without the limitations of my current solution. This new feature is now called Cached Data.

Cached Data Features

The basic principle behind this new feature is simple. First, allow the EDA client to define a Cached Data Request and specify the reporting frequency, data collection frequency, and other attributes like the number of samples, a start trigger, a stop trigger, and whether or not the triggers are cyclical. Then have the EDA server report the data for each parameter as a compact data array.

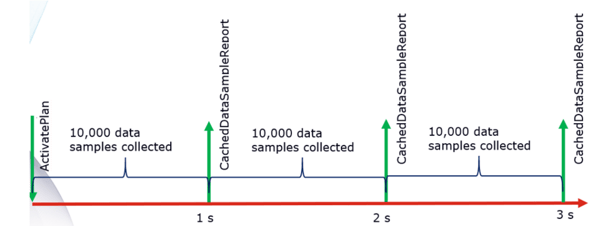

For example, an EDA client might ask for a parameter at a collection interval of 0.1 ms (10 KHz) and a reporting interval of 1 second. The result would be a set of Cached Data Reports that look like this:

The equipment would collect the data every 0.1 ms and store the values for 1 second, and then send the Cached Data Report with the collected values in a tightly packed array. The EDA client would receive the data once per second and would know the data collection frequency.

Limitations

There are some limitations to the Cached Data proposal. For example, this type of data array reporting is only practical for some data types like integers, floats, Booleans and bytes. This type of data reporting is not practical for structured data or strings. Moreover, not all data can or should be collected at such high rates. Collecting data at these high rates requires robust software specifically designed for high-speed data collection. Therefore, the EDA proposal includes a way for parameter metadata to specify where the cached data feature can be used, and includes the specific minimum and maximum data collection frequencies. Therefore, the Cached Data feature is expected to be used for a limited subset of the available parameters for which the EDA server is specifically designed to provide such high-speed data collection.

gRPC & Protocol Buffers

The proposed EDA Freeze 3 standards also include the use of gRPC and Protocol Buffer technology, thereby moving EDA away from SOAP/XML over HTTP. gRPC with Protocol Buffers is a solution for a binary interface. Prelimiary test results reported to the DDA task force show dramatic throughput improvements and reduced bandwidth requirements for EDA. Additionally, the testing confirmed that reporting data in compact arrays is far more efficient for transmitting large amounts of data. In other words, the Cached Data feature is expected be even more effective due to this EDA protocol change.

SEMI Voting

Soon a new voting cycle for SEMI standards will begin where we vote on new versions of the standard. The Cached Data feature is included in two SEMI ballots: ballot 6553, a major revision of the SEMI E134 SPECIFICATION FOR DATA COLLECTION MANAGEMENT, and ballot 6527, a major revision of the SEMI E125 SPECIFICATION FOR EQUIPMENT SELF DESCRIPTION. Both are planned for voting in SEMI voting cycle 2 in 2020. Task force members are currently reviewing the latest revision of the proposed ballots.

Studies have already shown vast improvements in factory applications when collecting data at 10 Hz instead of 1 Hz. The increased performance of EDA Freeze 3 will allow the industry to dramatically improve manufacturing processes even more when data can be collected and reported at rates of 1000 Hz, 10 KHz, and beyond.