Recently, I had the opportunity to participate in the development, testing, and integration of the Cimetrix ELS library that encompasses the SEMI A1, A1.1, and A2 (SMT-ELS) standards. It’s been exciting to see how ELS has increasingly been embraced as a connectivity solution for electronic manufacturing equipment.

I was first introduced to the SMT-ELS standard in June 2019 by Alan Weber (VP, New Product Innovations, Cimetrix). To begin, I obtained a functioning ELS implementation from Siemens Japan as well as the needed hardware. To make sure I fully understood ELS, I attended a 2-day class presented by Siemens and began studying the ELS standard and the Siemens ELS implementation.

It took a significant amount of time to get familiar with Siemens Implementation and gain an understanding of what they did to support the ELS standard. Siemens Japan has done a great job with their SEMI SMT-ELS implementation, and their assistance with my efforts is greatly appreciated. Once I felt familiar enough with ELS, I built a SMEMA interface driver to simulate the conveyor signals.

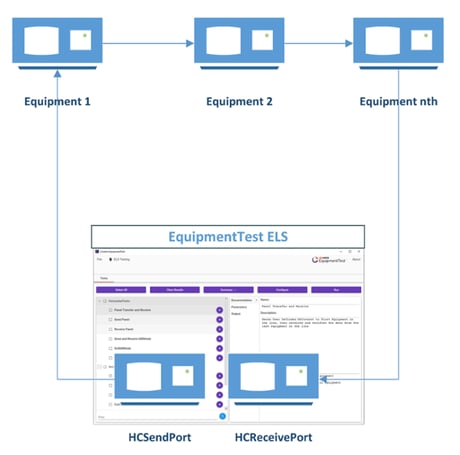

Using the SMT-ELS communications library, the Cimetrix development team designed a sample equipment application which I was able to use for initial connectivity testing. At first, it was fairly difficult to get the two libraries to communicate. However, when I used the Cimetrix EquipmentTestTM software, I was able to find defects in our library, which were quickly and easily resolved by our development team.

While it was beneficial to have a known ELS implementation to test against, it is now clear how valuable using a testing tool would be for anyone creating or validating their own SEMI SMT-ELS implementation.

Even though the SEMI A1, A1.1 and A2 standards are not long, they are dense. As adoption of these standards increases, it becomes paramount that equipment manufactures can test their SMT-ELS implementations during development. It is not effective or efficient for equipment manufacturers to test against other equipment as their primary form of testing. This is why the Cimetrix EquipmentTest SMT-ELS plug-in is so valuable.

I am currently working on test are written in C# and the code is easy to follow. The tests are split into two categories; one for horizontal communication between equipment ,and vertical communication to a factory system.

Horizontal Tests

For Panel Transfer verification, EquipmentTest connects to the first and last equipment in the line. This allows EquipmentTest to send messages to the first equipment and validate the format and content of the message from the last equipment.

For this test, the user defines the panel parameters. The panel is sent to the first equipment. Once the last equipment in the line sends the panel to EquipmentTest, the Material Data Content is verified.

In addition to actual tests, EquipmentTest can be used to send user defined atomic messages such as SetMDMode.

Vertical Tests

EquipmentTest Connects directly to the vertical port of the equipment. Using EquipmentTest, I can set and validate the Net Configuration.

The EquipmentTest software has been pivotal in developing and test our SMT-ELS Implementation. A demonstration of EquipmentTest SMT-ELS and the Cimetrix EquipmentConnectTM SMT-ELS software will be given at Productronica from November 12-15, 2019 in Munich, Germany. Please drop by our booth any time, or feel free to set up an appointment in advance. We look forward to meeting with you and discussing your ELS needs!