by David Warren,

Senior Software Engineer, CIMControlFramework Solution Architect

Part 2 - Read Part 1

Would it surprise you to find out there are still people who pan for gold? Some are serious prospectors working for a payoff. Others are recreational prospectors who enjoy the outdoor activity and the actual finding of gold is of secondary importance. Regardless of their motivation, most prospectors must sift a great deal of material in order to find a few flakes of gold. Having the right equipment helps the serious prospector to sift more material and find gold more quickly than someone just looking for a good time.

What does panning for gold have to do with Cimetrix? In a previous blog, we talked about the importance of having log data when problems occur. Log data can be like panning for gold—most of the log data has little to do with the problem you are currently trying to solve, but a few of the messages will be pure gold. Having the right tools to find the gold log messages quickly can make all the difference in the world in resolving problems in a timely manner.

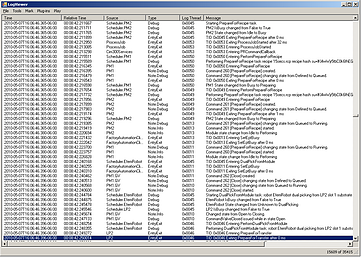

Analyzing tens of megabytes of text data with a text editor and a pair of Mark I eyeballs is difficult at best. Yes, text editors do have the ability to search for words or phrases, but that only helps if you already know what you’re looking for. Jumping into the middle of a log file lets you look at the messages in that part of the file, but gives you no context into what has happened before or after the log messages you are looking at.

CIMControlFramework, our tool control solution, contains a Log Viewer application to help analyze CIMControlFramework log files. It has standard text analysis features such as text search and bookmarking, but because it understands CIMControlFramework log messages, it has more powerful features as well. It adds features like time deltas, finding matching messages for function entry and exits, and tracing a single thread’s log messages. But its most powerful feature is being extensible through plug-ins. These plug-ins have the ability to analyze all the log messages and graphically display information to give context to the current log messages.

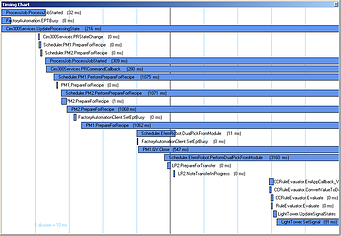

One such plug-in is the Timing Chart. The Timing Chart looks at all the function entry/exit log messages and creates a timing chart centered on the current log message. This allows you to look at all the functions that are currently being executed and how long each function took to complete. It also shows which functions just finished and which functions are about to start. It just wouldn’t be feasible to keep track of all that information manually. Another plug-in tracks wafers as they move through tool. A third plug-in keeps track of GEM300 job data. And you are not limited to our ideas for plug-ins, you can develop your own to display the log data however you want.

One such plug-in is the Timing Chart. The Timing Chart looks at all the function entry/exit log messages and creates a timing chart centered on the current log message. This allows you to look at all the functions that are currently being executed and how long each function took to complete. It also shows which functions just finished and which functions are about to start. It just wouldn’t be feasible to keep track of all that information manually. Another plug-in tracks wafers as they move through tool. A third plug-in keeps track of GEM300 job data. And you are not limited to our ideas for plug-ins, you can develop your own to display the log data however you want.

Having the CIMControlFramework Log Viewer and its plug-ins helps you to sift through the log data and find the gold log messages quickly and efficiently. Finding the right log messages will enable you to resolve problems in a timely manner.

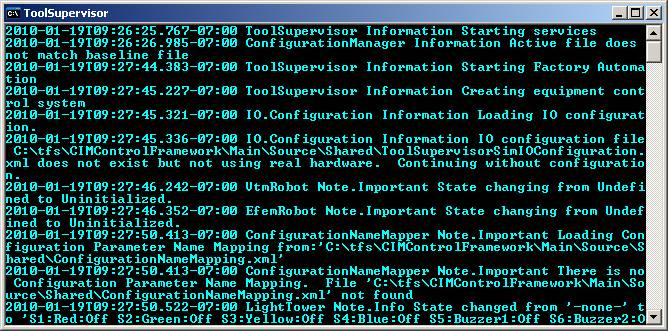

In today’s world, having great software is not enough. To be successful, software must also be supportable. Keeping a record of what the software is doing and has done enables after-the-fact diagnosis and makes remote support much more efficient. As an additional benefit, this information can also be displayed live to the GUI, giving the operator additional insight into what is happening. Having a record makes it possible to determine if the software is working correctly or incorrectly. In Cimetrix’s new tool control software, CIMControlFramework™, this functionality is provided by the Logging package.

In today’s world, having great software is not enough. To be successful, software must also be supportable. Keeping a record of what the software is doing and has done enables after-the-fact diagnosis and makes remote support much more efficient. As an additional benefit, this information can also be displayed live to the GUI, giving the operator additional insight into what is happening. Having a record makes it possible to determine if the software is working correctly or incorrectly. In Cimetrix’s new tool control software, CIMControlFramework™, this functionality is provided by the Logging package. Cimetrix and Rorze have been working together for several years with Rorze transitioning the FA for its Sorter line to Cimetrix

Cimetrix and Rorze have been working together for several years with Rorze transitioning the FA for its Sorter line to Cimetrix