by Brian Rubow

Quality Customer Support Manager

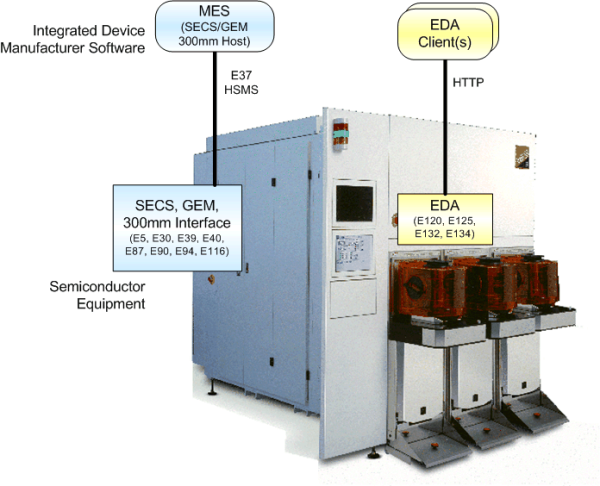

Equipment Data Acquisition (EDA), also known as Interface A, is a suite of SEMI standards developed to meet the demand for high-speed access to more and better process data.

The primary motivation for IC makers such as Intel and Samsung to implement EDA is the continued drive for productivity. In order to ensure compatibility between semiconductor equipment companies and semiconductor manufacturers EDA implementations, ISMI and its member companies have initiated the concept of "freeze versions”. A freeze version simply identifies a specific version of the EDA SEMI standards that ISMI members agree to use. The freeze version concept has allowed EDA to be deployed while allowing the EDA standards to continue to be enhanced.

The industry has adopted the initial ISMI 1105 freeze version for over 5 years. Recently, ISMI announced a new 0710 freeze version that specifies standards approved at the 2010 Spring SEMI standards meetings. The 0710 standards take advantage of what the industry learned since the original freeze version with many improvements and some new capabilities.

Equipment manufacturers developing systems to comply with the 1105 freeze version use Equipment Client Connection Emulator (ECCE) as reference client software to check their EDA solutions. Manufacturers developing equipment to comply with the new 0710 version will use a new EDA Reference Client to exercise and verify the EDA functionality available in the equipment. The new EDA Reference Client will be available from the Cimetrix web site by April 30, 2011.

If you would like more information about what is in the new freeze version, take a look at the November 30, 2010 e-Manufacturing workshop presentation on the ISMI web site:

I have been a Scoutmaster for the Boy Scouts of America for about 5 years now. Our troop goes camping several times a year. Utah offers a lot of beautiful and interesting camping areas. The variety is remarkable. In our troop we spent a lot of time teaching and preparing the boys to not only have fun, but also be safe and wise in their fun. Some planning ahead, training and common sense can make a huge difference. Nearly every week, I have our Senior Patrol Leader help all of the scouts in our troop recite a number of memorized phrases including the Scout Oath, Law, Slogan, Motto and sometimes even the Outdoor Code. The Scout Motto is the famous one known to almost everyone in the world; "Be Prepared". Reciting it every week helps our minds to remember to focus on being prepared for whatever may come. We prepare the boys to handle emergency situations such as medical and weather related emergencies. "Be Prepared" applies not only to scouting activities like camping, canoeing and hiking, but also to school, our careers and everything we do.

I have been a Scoutmaster for the Boy Scouts of America for about 5 years now. Our troop goes camping several times a year. Utah offers a lot of beautiful and interesting camping areas. The variety is remarkable. In our troop we spent a lot of time teaching and preparing the boys to not only have fun, but also be safe and wise in their fun. Some planning ahead, training and common sense can make a huge difference. Nearly every week, I have our Senior Patrol Leader help all of the scouts in our troop recite a number of memorized phrases including the Scout Oath, Law, Slogan, Motto and sometimes even the Outdoor Code. The Scout Motto is the famous one known to almost everyone in the world; "Be Prepared". Reciting it every week helps our minds to remember to focus on being prepared for whatever may come. We prepare the boys to handle emergency situations such as medical and weather related emergencies. "Be Prepared" applies not only to scouting activities like camping, canoeing and hiking, but also to school, our careers and everything we do. I have a lot of children—seven. Many of them are still young. Sure it is a lot of fun. However, more often than I like (yet not terribly often since I have really good kids), I get caught in the middle of a “he said/no I didn’t” dispute. That is where one of my children shows up in a huff to wherever I am and reports what “he said”, he meaning another one of my children. Then in the background I’ll hear the other one say either the “no I didn’t’ or the “but that’s because he said” response. And both kids look at me and expect the impartial judge (a.k.a. me) to do something. Each of them will give the impression of complete honesty and full recollection, yet they cannot agree about what happened or about what the other said.

I have a lot of children—seven. Many of them are still young. Sure it is a lot of fun. However, more often than I like (yet not terribly often since I have really good kids), I get caught in the middle of a “he said/no I didn’t” dispute. That is where one of my children shows up in a huff to wherever I am and reports what “he said”, he meaning another one of my children. Then in the background I’ll hear the other one say either the “no I didn’t’ or the “but that’s because he said” response. And both kids look at me and expect the impartial judge (a.k.a. me) to do something. Each of them will give the impression of complete honesty and full recollection, yet they cannot agree about what happened or about what the other said.