To start off our SECS/GEM series, let's begin with an explanation of one of the GEM standard’s key features called Collection Events. We'll start with an explanation as to how they work, then move to why they are so effective for collecting data from manufacturing equipment.

What are collection events?

The two words in the name “collection event” are descriptive.

As denoted by the word “event” a collection event is a notification. Its purpose is to notify the host when something of interest happens at the equipment. The “host” is the factory client software that connects to the equipment’s GEM interface. For example, collection events can report when material arrived, a consumable is running low, a hardware problem occurred, a camera inspected the material, the material is ready to be removed, a chamber reached the target vacuum pressure, processing completion, etc. The equipment can use the collection event feature to report when anything of interest happens. Whoever makes the GEM interface determines exactly what collection events are available to the host; therefore the set of available collection events is different from equipment type to equipment type.

As denoted by the word “collection”, collection events are also capable of publishing data along with the collection event message. It is a very efficient form of data collection, asynchronously providing information as it becomes available. For example, a collection event that reports when material arrives might also report the arriving material’s barcode and location. There are three types of data in a GEM interface; information about the collection event (called data variables), status information (called status variables) and equipment settings (called equipment constants). Whoever makes the GEM interface determines exactly what information will be available for each collection event. So the set of available information for collection events is different from equipment type to equipment type. And the available data is only sent if the host sets up the reports.

So in summary, a collection event can not only tell the host when something happens but it can also provide more detailed information about what happened and about the status of the equipment.

A little analogy

As an analogy, think of the factory as a boss and the equipment they purchase as employees. There are many different styles of managing, just like there are different types of factories and styles for running a factory. You don’t want to be forced to run your factory just like someone else’s factory. You want to run it your way.

As an analogy, think of the factory as a boss and the equipment they purchase as employees. There are many different styles of managing, just like there are different types of factories and styles for running a factory. You don’t want to be forced to run your factory just like someone else’s factory. You want to run it your way.

Additionally, each employee is unique and needs unique level of attention. And each employee is doing unique things. Generally speaking, all managers want to know basic information about employees and what their employees are doing. They want to know when the employee starts a project and when they finish a project. Some employees are very productive even with minimal oversight and reporting. Some employees need extensive oversight and reporting. GEM allow the factory to deal with each equipment uniquely. Specifically, GEM collection events give the equipment a way to report on what it is doing.

The host has to set up the rules for the reporting and adapt the rules appropriately. For example, sometimes a manager does not care when the employee goes to the bathroom. For certain employees, the manager might want to know. In a GEM interface, the host can choose which notifications occur and which do not.

Sometimes a manager just needs to be told when the employee does things like when employee arrives, departs, goes on break, and come off break. Sometimes a manager needs more details, like what project did you finish, how long did it take, the key results of the project. Similarly, GEM allows the host to track not when things happen, but to also provide details about the activity. GEM reports meet this need very effectively.

Why do you need this feature?

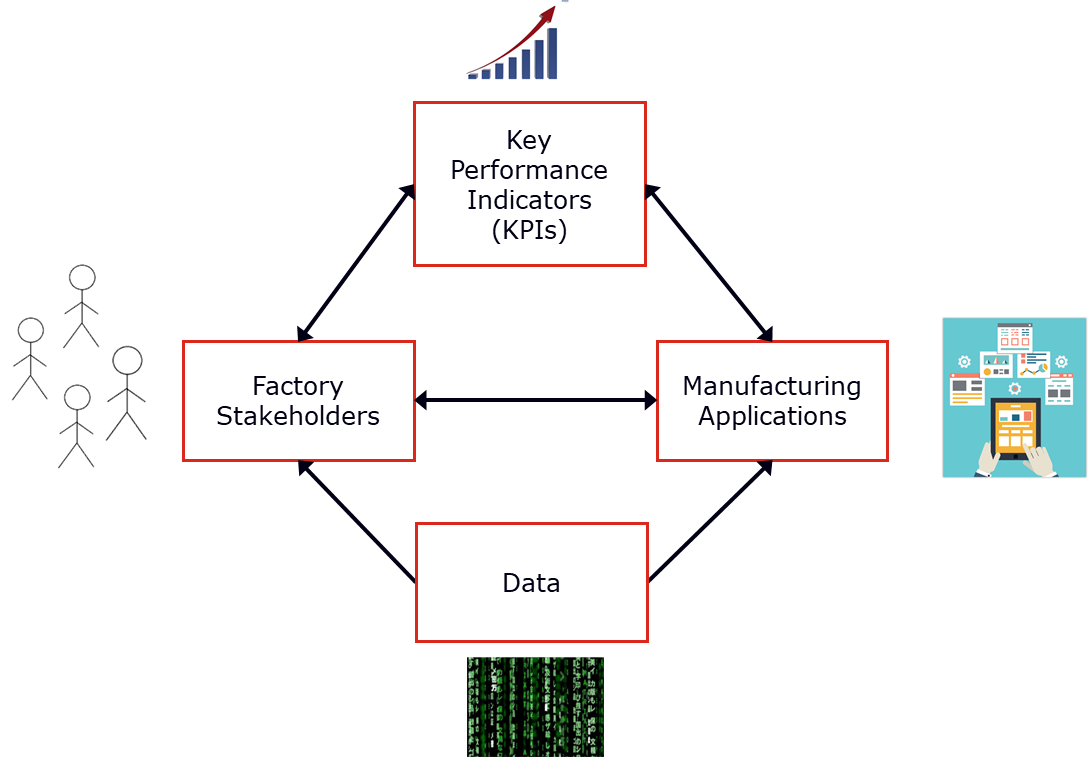

The short answer is that collection events allow you to track what the equipment is doing in real time. If a factory wants to any degree of Smart Manufacturing or just wants to improve productivity, then one of the first things needed is the ability to track what the equipment is doing. Collection events provide this. You can track equipment utilization, material movement, processing milestones, count cycles of activity for predictive maintenance, consumable usage, and anything else related to the published collection events. The applications for such information are endless.

Sometimes collection events are also used to implement scenarios where the equipment needs information from the host before proceeding or permission to proceed. A collection event tells the host when the equipment is ready for the host instructions or permission.

How does the collection event notification work?

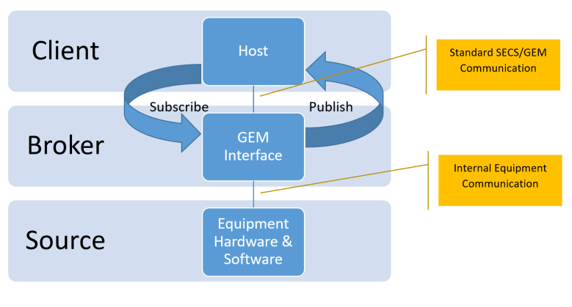

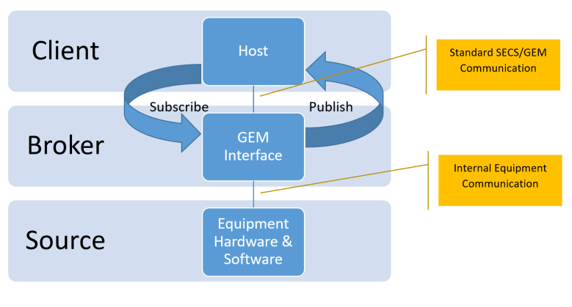

An equipment’s GEM interface can publish many different collection events. The host will not typically want to be notified of all of them at once and it does not have to. Collection events use a publish/subscribe design pattern in two ways.

Basic Publish/Subscribe Notification

The host subscribes to specific collection events to receive notification when they occur. The subscription allows a host to enable or disable the reporting of each collection event available in the GEM interface. The equipment publishes the collection events as they happen.

Event Report Publish/Subscribe Data Collection

By default, a collection event message will not include any data. A subscription also allows the host to decide what data to include in each enabled collection event’s message. The host defines reports and links the reports to collection events; thereby subscribing to the data. Each collection event can have a different report. Reports can also be shared across multiple collection events. A report can include any data variables associated with the collection event, any status variables and any equipment constants. The equipment publishes the collection event with the requested data.

Identification

Each collection event published by the equipment has a unique ID number for identification. The host software uses the ID number when enabling or disabling a collection event. The equipment uses the ID number when the collection event message is sent. Each available data variable, status variable and equipment constant also has a unique ID number. When the host defines a report, it assigned the report a unique ID number.

Broker

The broker to handle all collection event publication/subscription is built into the equipment’s GEM interface. It is part of the equipment system. Communication between the host (a client) and GEM interface is standardized using SECS/GEM communication. Communication between the GEM interface and the rest of the equipment hardware and software (the source of the equipment collection events and data) can be any appropriate technology and does not matter as long as the GEM interface functions properly and performs sufficiently well.

This means that messages are only sent from the equipment to the host when the host has subscribed. Having the broker as part of the equipment and GEM interface makes the GEM interface very efficient and use much less bandwidth than protocols that use an external broker where all messages and data have to be sent to a broker all the time.

Persistence

The collection event subscriptions are persisted in a GEM interface. So if the host disconnects and reconnects, or if the equipment is restarted, the GEM interface will remember the setup of all subscriptions.

Which messages are used?

Here is a summary of each of the primary messages related to collection events. Note that the “S” identifies the “stream” and “F” identifies the “function”. Together, a stream and function number uniquely identify a message.

| Message ID |

Direction |

Description |

| S2F37 |

Host -> Equipment |

Enable or disable reporting for a set of collection events.

An empty list will enable or disable the reporting for all collection events. Enabling all collection event reporting is useful when characterizing a GEM interface. Disabling all collection events is useful before enabling the reporting of desired collection events. |

| S2F33 |

Host -> Equipment |

Define one or more reports.

An empty list will delete all reports as well as the report links to collection events. Deleting all reports is a useful when resetting the subscriptions, or when connecting to a GEM interface for the first time to override default subscriptions. |

| S2F35 |

Host -> Equipment |

Link one or more reports to a set of collection events.

If reports are already linked to a collection event, you have to remove them and then link all collection events in one message. An empty list will remove report links from the collection event. |

| S1F23 |

Host -> Equipment |

Request the list of available collection events and the available data for each collection event. |

| S6F11 |

Equipment -> Host |

The collection event message.

If no reports are linked, the message will only include the collection event ID number. If one or more reports are linked to the collection event, then the report data for each linked report will be included in the message. |

Frequently Asked Questions about Collection Events

How much bandwidth do collection events require?

This depends on several factors.

- The number of collection events that are enabled by the host.

- The size of the data reports linked to the collection events.

- The frequency at which the enabled collection events are triggered by the equipment. This depends on the meaning of the collection event.

How fast can collection events be triggered?

The GEM standard does not limit collection event frequency and uses standard communication hardware. In other words, by improving the hardware you can allow for faster collection events.

GEM allows for two protocols: SECS-I and HSMS. SECS-I is based on RS-232 serial communication and therefore little used today. Such implementations are not able to trigger collection events very quickly.

HSMS is based on network communication. Because serial communication is slow, by far most GEM implementations use HSMS. GEM uses TCP/IP very efficiently. The possible frequency of collection events depends on the speed of the network hardware, equipment computer performance, and host computer performance. Like most protocols, it usually takes more computer resources to consume messages than it does to produce them.

The speed at which collection events can be generated also depends on the data reports linked to the collection events. For example, if a data report is large, like 10 MB, this will impact performance.

Why aren’t I receiving the collection event messages?

There are a few reasons why a host might not receive collection event messages.

- Host and equipment must have established GEM communication using a successful S1F13/S1F14 exchange.

- GEM control state must be on-line. It cannot be in a host-offline or equipment-offline state.

- GEM spooling must be inactive. To disable spooling while it is active will not make spooling go inactive. If the spooled messages are not wanted, then purge spooling using message S6F23. If the spooled messages are wanted, then request them iteratively using S6F23 until the spooling state becomes inactive.

- The collection event must be enabled. Use S1F3 to check the “EventsEnabled” status variable to confirm that the collection event is enabled. Use message S2F37 to enable the collection event.

- The collection event activity needs to occur. For example, a collection event reporting when material arrives will never occur if material does not actually arrive. If the activity happens and the above conditions are satisfied, then the equipment’s GEM interface has a defect.

What if an equipment’s GEM interface does not publish the collection event I need?

Ask the equipment supplier to add the desired collection event. It is difficult for an equipment supplier to accurately predict all collection events that the factories will want. The equipment supplier will need to upgrade their GEM interface software at the factory.

How large of data reports can be when linked to a collection event?

GEM allows a single data variable value or status variable value to be an array or structure of any data type including a floating point, string or integer. A single array is limited to 16.777215 MB. Total message size is limited to 4.294967295 GB.

To download a white paper on an introduction to SECS/GEM, Click below:

Following several SECS/GEM series blog posts, including Collection Events, Data Polling and Alarms, we now get into the features and merit of the GEM feature called Recipe Management. We will cover the definition of recipes, what recipe management means and why you need this feature!

Following several SECS/GEM series blog posts, including Collection Events, Data Polling and Alarms, we now get into the features and merit of the GEM feature called Recipe Management. We will cover the definition of recipes, what recipe management means and why you need this feature!

Just like a home alarm system, semiconductor fabs want to know when something bad has happened. They want to prevent the material being processed from being scrapped. Alarm management enables the equipment to notify the host when something goes wrong, and provide information about what has gone wrong. The GEM standard defines Alarm Management as the capability to provide host notification and management of alarm conditions occurring on the equipment.

Just like a home alarm system, semiconductor fabs want to know when something bad has happened. They want to prevent the material being processed from being scrapped. Alarm management enables the equipment to notify the host when something goes wrong, and provide information about what has gone wrong. The GEM standard defines Alarm Management as the capability to provide host notification and management of alarm conditions occurring on the equipment.  condition occurs. Communicating that additional information to the host is valuable, but cannot be done through the normal Alarm Report Send/Acknowledge messages. To provide a way to get this additional information, GEM requires that two collection events be defined for each possible alarm condition on the equipment – one event for when the alarm is set, and another for when the alarm is cleared. These collection events allow the GEM event data collection mechanisms to be used to send the additional related information to the host when an alarm changes state.

condition occurs. Communicating that additional information to the host is valuable, but cannot be done through the normal Alarm Report Send/Acknowledge messages. To provide a way to get this additional information, GEM requires that two collection events be defined for each possible alarm condition on the equipment – one event for when the alarm is set, and another for when the alarm is cleared. These collection events allow the GEM event data collection mechanisms to be used to send the additional related information to the host when an alarm changes state.

Types of Data

Types of Data