Welcome to the first posting in the Cimetrix CIMControlFramework (CCF) Services blog series! While Cimetrix has been providing professional services for many years, in order to better serve the growing demand from many new equipment maker customers worldwide that have purchased our CCF product, Cimetrix earlier this year formed a new CCF Services group, reporting directly to the CEO. Being a senior developer at Cimetrix for the past 15 years in a variety of positions, I was delighted when asked to lead this group. We have an outstanding team of software engineers highly experienced in factory automation, equipment control software and SEMI standards. We are dedicated to ensuring our customers’ success by providing training, consulting, and developing custom solutions for our CCF customers. We love learning about the myriad ways that companies can integrate CCF with their equipment to meet the material handling and factory automation requirements of their factory customers. Our goal for these articles is to share some of the lessons learned and other implementation insights to help you efficiently build manufacturing equipment that is sophisticated, robust, and productive. To this end, our first posting will deal with one of the most common requests we get – enjoy!

- Forward by Brent Forsgren, Director of CCF Services

How we helped a customer deliver a GEM-compliant equipment using CCF

The Goal

One of our recent customers wanted to build a new type of LED manufacturing equipment that could be controlled by a Factory Host using the standard GEM Remote Commands: PP_SELECT (Process Program Select), START, STOP, ABORT, PAUSE and RESUME. The equipment could be delivered in a variety of physical configurations, including 1-to-multiple source cassettes for product material, and 1-to-multiple process modules. It also had multiple destination cassettes to be filled according to the post-process analysis results. The initial instance of the equipment had 4 loadports (LPs) and four process modules (PMs).

The functional requirements were clear – that was the good news. Now for the rest of the story… the project schedule and budget constraints were closing in, so we needed to work quickly and efficiently with the customer to get it done. Sound familiar?

The Approach

The Cimetrix CCF Services team always works closely with the software team of the equipment manufacturer. In this case, we started with one week of mutual discovery and in-depth hands-on training. Team members were fully engaged and picked up the CCF capabilities very quickly. This included even some of the more advanced features, such as developing a scheduler that would control the components of the customer’s application. We regularly fine tune training modules to 1) introduce CCF concepts, 2) expose common challenges and potential approaches, and 3) provide realistic implementation practice exercises. As anticipated, the customer was able to use the results of the training exercises in the actual equipment control solution. We also kicked off the project with our work-breakdown exercise to more deeply explore the unique requirements for their specific equipment type.

After an intense first week, everyone on the project team concluded that CCF would in fact be a strong match for their needs. CCF features direct integration with our CIMConnect, CIM300, and CIMPortal connectivity products to provide full GEM, GEM300 and EDA compliance. Because the Cimetrix connectivity products are deployed in every semiconductor 300mm factory in the world, our customers can be assured that they will meet their customer’s factory automation requirements. In this application, the end customer’s LED factory only required GEM.

To address requirements that may go beyond the basic GEM standards, CCF also provides support for custom remote commands, data publication, and alarm management. Finally, CCF supports integrating custom hardware devices using CCF’s base Equipment Classes.

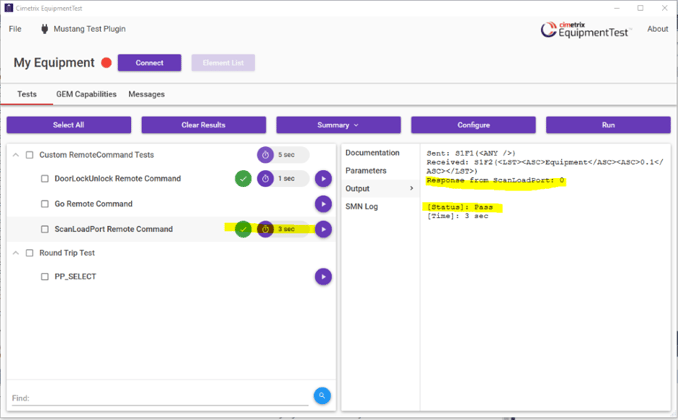

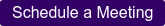

To prove all was working, we chose the Cimetrix EquipmentTest product to develop and execute a set of unit tests that emulate communications with the factory software using GEM messages. This was not intended to be a comprehensive set, but rather just enough to show the equipment passed round-trip system testing. In this context, round trip means showing that the equipment can move material from the incoming cassette to the aligner to the process module and back into the cassette. EquipmentTest also supports editing message settings and parameters on the fly to experiment with different configurations of a round-trip test.

The Challenge: “The Host is unavailable, but we need to validate that the equipment is both GEM compliant and accomplishes the communication flows the end user requires.”

We get this challenge a lot… Our customers almost always develop the host interface and the embedded control software in parallel and integrate them later in the project. This makes sense at one level, but it does introduce a “chicken and egg” problem for testing this kind of GEM interface. In particular, how can our customer provide evidence that the solution will work with the factory host without testing with the actual host system? Our answer: apply our EquipmentTest custom plugin capability to simulate the end user’s host so we can validate all necessary communication between host and equipment.

Our protocol validation product, EquipmentTest, makes it possible to simulate communications between an equipment control implementation and the host. And although it is impractical to implement scenarios for every possible interaction, we can create enough representative scenarios to be confident the “happy path” (i.e., no errors) will work and that the interface will handle a large handful of “sad path” cases as well.

Outcome

We passed all the tests! “Let’s go get some tacos.”

Specifically, we validated that the communications interface supported…

- Standard GEM Remote Commands

- Custom Remote Commands

- Material tracking

- Data publication

In closing, we must emphasize that our customer should take most of the credit here. Nevertheless, we enjoyed observing, consulting, and testing the equipment. It is always gratifying to see the CCF solution fit so seamlessly into the hardware, execute its commands with optimal timing, and not break anything in the process! Truly a successful, joint team effort.

If the situation above resonates with your current challenges and past experiences, give us a call. We look forward to working with your software engineering team to speed your time-to-market and deliver a high-quality solution quickly, allowing your team members to focus on developing value-added functionality for your customers.

.png?width=164&name=MicrosoftTeams-image%20(21).png) Cimetrix is pleased to announce and welcome Thomas Simon as its Director of Sales of Cimetrix Europe and Managing Director of Cimetrix GmbH. Thomas is based in Munich, Germany and will lead our growth in Europe. Thomas Simon will be responsible for ensuring the success of our growing customer base of leading semiconductor equipment manufacturers and smart manufacturing factories in Europe, providing strategic direction for Cimetrix Europe to have long-term success in the European market, overseeing local sales and account management and leading an expert team of Europe-based software engineers.

Cimetrix is pleased to announce and welcome Thomas Simon as its Director of Sales of Cimetrix Europe and Managing Director of Cimetrix GmbH. Thomas is based in Munich, Germany and will lead our growth in Europe. Thomas Simon will be responsible for ensuring the success of our growing customer base of leading semiconductor equipment manufacturers and smart manufacturing factories in Europe, providing strategic direction for Cimetrix Europe to have long-term success in the European market, overseeing local sales and account management and leading an expert team of Europe-based software engineers.

Meet Anderson, a member of our Solutions Engineering team. Anderson lives and works in South Korea, and is an integral part of our Korea office. Read on to learn a little bit more about Anderson.

Meet Anderson, a member of our Solutions Engineering team. Anderson lives and works in South Korea, and is an integral part of our Korea office. Read on to learn a little bit more about Anderson. Meet Rich Kingsford

Meet Rich Kingsford

Meet Brent Forsgren, the Director of CCF Services at Cimetrix. Read on to learn a little bit more about Brent.

Meet Brent Forsgren, the Director of CCF Services at Cimetrix. Read on to learn a little bit more about Brent. Meet Samson, a member of our Solutions Engineering team. Samson lives in Taiwan and is an integral part of our Taiwan team. Read on to learn a little bit more about Samson.

Meet Samson, a member of our Solutions Engineering team. Samson lives in Taiwan and is an integral part of our Taiwan team. Read on to learn a little bit more about Samson.