Can you think of a better place to spend time with customers and partners than Munich, Germany during Productronica and SEMICON Europa trade fairs? SEMICON Europa has had dwindling attendance in the past few years, even in a hot semiconductor market, so SEMI decided to combine with the robust Productronica for 2017. It was a great decision. This trade fair had 8 full and busy halls as a result; with high spirits from all attendees. Four of the Productronica halls were dedicated to the SMT industry (Surface Mount Technology) which is part of what we call Electronics Assembly. This industry is wrestling with moving to Smart Manufacturing and Industry 4.0. What better way to learn than to have SEMICON Europa next door? SEMICON Europa occupied 1.5 halls filled with many of our current customers.

Can you think of a better place to spend time with customers and partners than Munich, Germany during Productronica and SEMICON Europa trade fairs? SEMICON Europa has had dwindling attendance in the past few years, even in a hot semiconductor market, so SEMI decided to combine with the robust Productronica for 2017. It was a great decision. This trade fair had 8 full and busy halls as a result; with high spirits from all attendees. Four of the Productronica halls were dedicated to the SMT industry (Surface Mount Technology) which is part of what we call Electronics Assembly. This industry is wrestling with moving to Smart Manufacturing and Industry 4.0. What better way to learn than to have SEMICON Europa next door? SEMICON Europa occupied 1.5 halls filled with many of our current customers.

Cimetrix decided to place our booth in one of the four SMT halls because we have a lot to offer the SMT industry in their migration to Smart Manufacturing. We had many visitors and discussions on how Cimetrix can help. There are a variety of ways used in SMT to gather equipment data including older “one way” standards, GEM, and several proposed new standards and our 25+ year heritage in semiconductor equipment automation ideally positions Cimetrix to help customers think through these options. We also brought extra staff to the show so we could spend time in the SEMICON Europa halls having scheduled meetings with our major European equipment suppliers and factories. Several new opportunities were brought to our attention and updates/planning for 2018 were discussed.

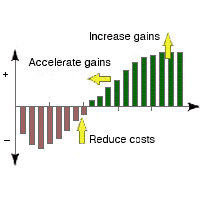

By far, the dominant theme at the show was Industry 4.0 and Smart Manufacturing. There were many excellent presentations in the Tech Arenas; and almost every booth had posters on the move to Smart Manufacturing. Of note were presentations by Dr. Jan Rothe from GLOBALFOUNDRIES and Jorg Richstein from Jabil discussing their automation plans for SMART Manufacturing; and Dr. Martin Schellenberger from Fraunhofer with a comprehensive set of steps to help companies understand Smart Manufacturing and the steps to get there.

As a company that focuses on helping manufacturers achieve their automation goals, it is hard not to come away from Munich excited about the next 5 years in electronics manufacturing.

Austin, Texas was the site of this year’s conference, going back to its roots after almost 30 years. Because of its unique focus on equipment and process control technology for the semiconductor industry, and the consistently high quality of its technical content, this conference continues to attract both industry veterans and newcomers to this domain, with this year’s attendance over 160.

Austin, Texas was the site of this year’s conference, going back to its roots after almost 30 years. Because of its unique focus on equipment and process control technology for the semiconductor industry, and the consistently high quality of its technical content, this conference continues to attract both industry veterans and newcomers to this domain, with this year’s attendance over 160.

Join us as we meet the Leadership Team of Cimetrix in our “Meet the Team” series.

Join us as we meet the Leadership Team of Cimetrix in our “Meet the Team” series.

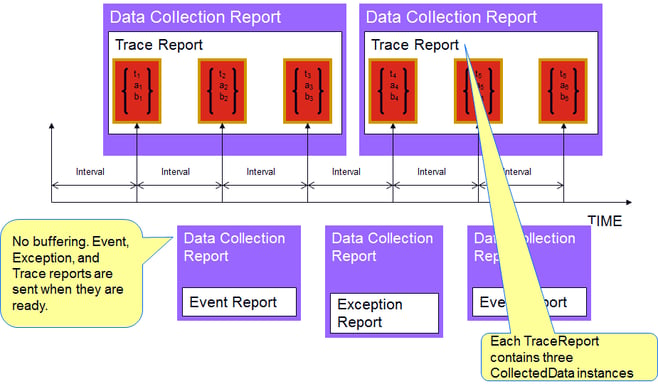

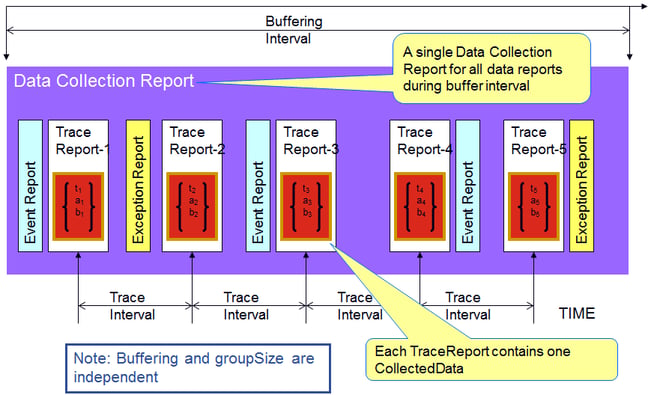

Buffering

Buffering

Join us as we meet the Leadership Team of Cimetrix in our “Meet the Team” series.

Join us as we meet the Leadership Team of Cimetrix in our “Meet the Team” series. Join us as we meet the Leadership Team of Cimetrix in our “Meet the Team” series.

Join us as we meet the Leadership Team of Cimetrix in our “Meet the Team” series.