The past few months have been full of news regarding adoption of the SEMI EDA (Equipment Data Acquisition, or Interface A) suite of standards by a number of major semiconductor manufacturers, which has quickly rippled throughout the supplier community as equipment makers and software providers alike consider the implications for their product road maps and support teams.

The range of EDA-related projects now underway covers the full spectrum from basic experimentation with this new data collection paradigm on a couple of tools to integration of these data sources with factory-level predictive analytics platforms to full factory pilot deployments. And although the specific requirements for the equipment suppliers involved in these projects may seem to be very different at the outset, eventually the fab purchasing departments will set a target for EDA interface functionality and performance that is high enough to support their automation requirements for the next 5-7 years.

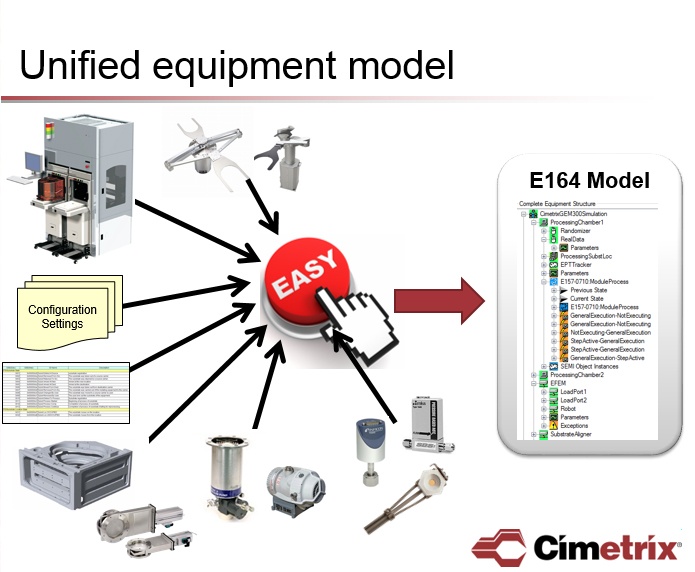

What this means in practice is that even though the current specifications may be fairly loose regarding which “Freeze” level (I or II) is called for and what the equipment metadata model structure and content should be, eventually the factory customers will fully understand the benefits they can achieve by requiring the latest versions of the entire EDA suite (especially the E164 Common Equipment Metadata standard), and will revise their specifications accordingly. For this reason, it makes perfect sense for equipment suppliers to plan for this level of implementation now rather than waiting for it to be required across the board. This is especially true for suppliers who are just beginning their EDA implementations, as it is no more difficult to build a Freeze II-/E164-compliant interface using today’s EDA development software products than a less capable interface.

From the factory customer usage perspective, it is important to consider the distinguishing features of the EDA standards when developing new purchasing specifications. In particular, unlike SECS/GEM, much of the EDA interface capability is dictated by the structure and content of the equipment metadata model, so this must be carefully designed to ensure that the automation requirements and performance expectations are clearly communicated. This may in turn require more direct involvement of the process, equipment, and industrial engineering teams than ever before.

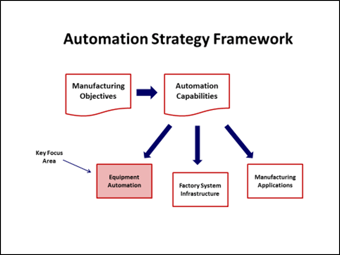

Moreover, when communicating these requirements to the OEM community, it is useful to explain what strategic manufacturing objectives are being addressed and what the information will be used for; this context helps the suppliers understand why the specs may include a high level of detailed information, and can shift a potentially adversarial negotiation process more towards a teaming relationship based on shared objectives.

Moreover, when communicating these requirements to the OEM community, it is useful to explain what strategic manufacturing objectives are being addressed and what the information will be used for; this context helps the suppliers understand why the specs may include a high level of detailed information, and can shift a potentially adversarial negotiation process more towards a teaming relationship based on shared objectives.

Fortunately, Cimetrix has many years of experience not only working in the EDA standards development process, but also providing products and services to the early fab adopters of this technology and most of their equipment suppliers. As a result, we have developed a pro forma set of EDA implementation guidelines which can easily be adapted to a specific factory’s purchasing requirements, and are happy to work with you to evaluate your needs and apply this process.

For more information about developing good EDA purchasing specifications, check out the video we’ve prepared at the link below – and then let us how we can help!