We live in a world where cell phone upgrades have become a way of life. Some people upgrade every time a new phone is available so that they can have the latest, greatest features and gadgets. Others prefer to keep their old phone since they are familiar with how it works and are satisfied with the phone’s functionality. While others still may upgrade because they have encountered a problem with their current phone that either can’t be fixed or has been addressed in the new model.

There are similar reasons to upgrade to a new version of a Cimetrix product. Here are a few sample questions that will help an OEM determine when is the best time to do so:

-

Is there an issue my customers are currently facing that has been addressed in the new version of the product?

Cimetrix works to fix customer-reported issues as well as issues found during internal testing. It is not possible to make these fixes in all previously released versions of the product, so they are made as a fix in the latest released version of the product. Upgrading to the latest version benefits the OEMs by providing fixes to issues they may have reported or, more often, to issues they haven’t seen but have been reported by other OEMs.

-

Are there added features or capabilities in the new version of the product that will improve my ability to support my customers and/or allow me to provide new functionality to my customers?

Cimetrix strives to support our customers by providing high-quality software products. As new technologies emerge and as scenarios in which our products are used evolve, we discover new ways to provide additional benefits to our OEM customers. These new capabilities are made available in new releases of our products. These improvements can include things like enhanced logging and diagnostic capabilities, new utilities for managing configuration files, or new screens for making setup easier.

-

Am I planning a new release of my equipment control software?

Like Cimetrix, OEMs are continually looking for ways to improve their equipment and provide new features and functionality to their customers. This means that they will periodically release new versions of their equipment that may contain new hardware and/or software functionality. This is an ideal time for OEMs to also upgrade their Cimetrix software so that their new platform can take advantage of the latest fixes and enhancements that are available.

This is by no means meant to be an exhaustive list of questions to be asked/answered when determining the right time to upgrade to a new version of a Cimetrix product, but it does give you an indication of the type of things that should factor into your decision-making process. Each new software release has a set of Release Notes that describe the software fixes and new features that have been added in that release. These Release Notes are there to help you make the best determination as to when to upgrade, so be sure to read them carefully. And, as always, the Cimetrix Support team is available to answer any questions and provide additional information if you should need it.♦

Cimetrix and our new distribution partner, Linkgenesis, participated in a joint booth at SEMICON Korea last week in Seoul. With over four exhibit halls located in the COEX Convention and Exhibition Center, SEMICON Korea is the largest SEMICON in terms of number of visitors—about 40,000—and included over 1,870 booths in 36,000 sq. meters of show space. The theme of the show was “Connect to Future, Market, People and Technology” with keynote speakers from leaders at Synopsys, Texas Instruments, and Audi. The show was co-located with LED Korea. Included in the schedule was also a meeting for the Information and Control Technical Committee, Korea Chapter, to work on SEMI standards.

Cimetrix and our new distribution partner, Linkgenesis, participated in a joint booth at SEMICON Korea last week in Seoul. With over four exhibit halls located in the COEX Convention and Exhibition Center, SEMICON Korea is the largest SEMICON in terms of number of visitors—about 40,000—and included over 1,870 booths in 36,000 sq. meters of show space. The theme of the show was “Connect to Future, Market, People and Technology” with keynote speakers from leaders at Synopsys, Texas Instruments, and Audi. The show was co-located with LED Korea. Included in the schedule was also a meeting for the Information and Control Technical Committee, Korea Chapter, to work on SEMI standards.

With unemployment rates at some of the lowest rates in 10 years, keeping good employees can be a challenge. Ownership in the company they work for is one benefit highly valued by many employees. We all want to be part of a growing business, make it successful, and know we will be rewarded for our hard work. Cimetrix wants to provide such ownership incentives to our employees and do it in such a way that is fair and motivating to the employees while being fiscally responsible to shareholders.

With unemployment rates at some of the lowest rates in 10 years, keeping good employees can be a challenge. Ownership in the company they work for is one benefit highly valued by many employees. We all want to be part of a growing business, make it successful, and know we will be rewarded for our hard work. Cimetrix wants to provide such ownership incentives to our employees and do it in such a way that is fair and motivating to the employees while being fiscally responsible to shareholders.

Linkgenesis will be exhibiting at SEMICON Korea 2016, which will be held in Seoul on January 27-29. Please stop by our booth in Hall C #1739 to see our product line as well as Cimetrix’ CIMPortal Plus, and discover how our software brings the latest innovations to the semiconductor manufacturing industry.

Linkgenesis will be exhibiting at SEMICON Korea 2016, which will be held in Seoul on January 27-29. Please stop by our booth in Hall C #1739 to see our product line as well as Cimetrix’ CIMPortal Plus, and discover how our software brings the latest innovations to the semiconductor manufacturing industry.

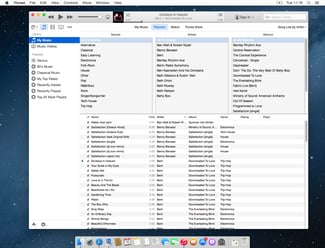

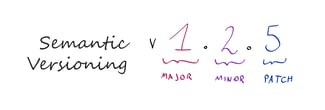

Many software companies can do this is through the way they use software versioning. It is common for software companies to use a major.minor.patch.build software versioning scheme, for example iTunes 12.3.1. This type of software versioning allows the software company to communicate the scale and impact of the changes in the release to their customers. A change in the “major” release number indicates to customers that there are some significant changes in this release that may impact the way it interacts with the product. The customer will likely need to make code changes or procedural changes when upgrading to such a release. A change to the “minor” release number denotes that there are multiple changes in the release, but customers should see only minor, or possibly no changes, in the way they use the product. A minor release may include some small new features that could potentially require code changes if the customers wants/needs those new features. A “patch” release is generally used to address a specific issue and should not change the customer experience with the software. The build number is most often provided to help the software company when researching a question or customer reported defect.

Many software companies can do this is through the way they use software versioning. It is common for software companies to use a major.minor.patch.build software versioning scheme, for example iTunes 12.3.1. This type of software versioning allows the software company to communicate the scale and impact of the changes in the release to their customers. A change in the “major” release number indicates to customers that there are some significant changes in this release that may impact the way it interacts with the product. The customer will likely need to make code changes or procedural changes when upgrading to such a release. A change to the “minor” release number denotes that there are multiple changes in the release, but customers should see only minor, or possibly no changes, in the way they use the product. A minor release may include some small new features that could potentially require code changes if the customers wants/needs those new features. A “patch” release is generally used to address a specific issue and should not change the customer experience with the software. The build number is most often provided to help the software company when researching a question or customer reported defect.

Last fall I was invited to attend the 30th Anniversary Celebration for Rorze Corporation and their partner company ADTEC Plasma Technology. The event took place at the Fukuyama New Castle Hotel in Fukuyama, Japan on December 14, 2015. As you may know, Rorze is an official distributor of Cimetrix products in Japan so we have a long-standing relationship including Rorze handling Cimetrix products as well as being an investor in Cimetrix Incorporated itself.

Last fall I was invited to attend the 30th Anniversary Celebration for Rorze Corporation and their partner company ADTEC Plasma Technology. The event took place at the Fukuyama New Castle Hotel in Fukuyama, Japan on December 14, 2015. As you may know, Rorze is an official distributor of Cimetrix products in Japan so we have a long-standing relationship including Rorze handling Cimetrix products as well as being an investor in Cimetrix Incorporated itself.

For a small company like Cimetrix, we can be proud of these accomplishments. We are very thankful to have had

For a small company like Cimetrix, we can be proud of these accomplishments. We are very thankful to have had