In the EDA Best Practices blog series, we have discussed choosing a commercial software platform, using that package to differentiate your data collection capabilities and how to choose what types of data to publish. In this post we will review why you should choose to provide an E164-compliant equipment model.

What is E164?

Equipment Data Acquisition (EDA) - also referred to as Interface A - offers semiconductor manufacturers the ability to collect a significant amount of data that is crucial to the manufacturing process. This data is represented on the equipment as a model, which is communicated to EDA clients as metadata sets. The metadata, based upon the SEMI E125 Specification for Equipment Self-Description, includes the equipment components, events, and exceptions, along with all the available data parameters.

Since the advent of the SEMI EDA standards, developers and fabs have recognized that equipment models, and the resulting metadata sets, can vary greatly. It is possible to create vastly different models for similar pieces of equipment and have both models be compliant with the EDA standards. This makes it difficult for the factories to know where to find the data they are interested in from one type of equipment to another.

Recognizing this issue, the early adopters of the EDA standards launched an initiative in to make the transition to EDA easier and ensure consistency of equipment models and metadata from equipment to equipment. This effort resulted in the E164 EDA Common Metadata standard, approved in July 2012. Another part of this initiative was the development of the Metadata Conformance Analyzer (MCA), which is a utility that tests conformance to this standard. With this specification, equipment modeling is more clearly defined and provides more consistent models between equipment suppliers. This makes it easier for EDA/Interface A users to navigate models and find the data they need.

Power of E164

The E164 standard requires strict name enforcement for events called out in the GEM300 SEMI standards. It also requires that all state machines contain all of the transitions and in the right order as those called out in the GEM300 standards. This includes state machines in E90 for substrate locations and in E157 for process management. The states and transition names in these state machines must match the names specified in the GEM300 standards.

These requirements may seem unnecessarily strict, but implementing the common metadata standard results in:

- Consistent implementations of GEM300

- Commonality across equipment types

- Automation of many data collection processes

- Less work to interpret collected data

- Ability for true “plug and play” applications

- Major increases in application software engineering efficiency

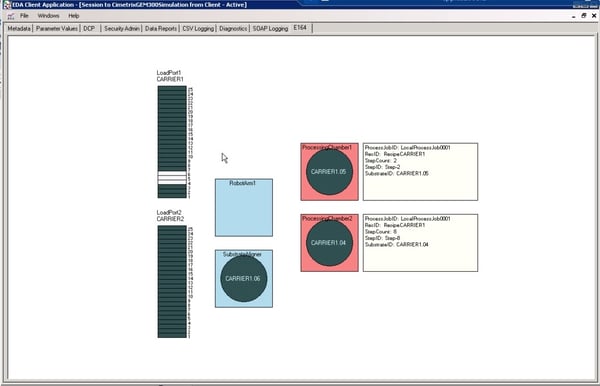

Knowing that a model is E164 compliant allows EDA client applications to easily and programmatically define data collection plans knowing that the compliant models must provide all of the specified data with the specified names. For example, the following application is able to track carrier arrival and slotmap information as well as movement of material through a piece of equipment and process data for that equipment.

This application will work for any GEM300 equipment that is E164 compliant. The client application developer can confidently create data collection plans for these state machines, knowing that an E164-compliant model must provide the needed state machines and data with the proscribed names.

Decide to be E164 compliant

A number of leading semiconductor manufacturers around the globe have seen the power of requiring their equipment suppliers to provide EDA/E164 on their equipment, and now require it in their purchase specifications.

If you are a semiconductor manufacturer, you should seriously consider doing the same because it will greatly simplify data collection from the equipment (and most of your candidate suppliers probably have an implementation available or underway.

If you are an equipment supplier and your factory customers have not required that your EDA models be E164 compliant, you should still seriously consider providing this capability anyway as a way to differentiate your equipment. Moveover, E164-compliant models are fully compliant with all other EDA standards. Finally, it is much easier and more cost effective to create E164-compliant models from the outset than it is to create non-compliant models and then convert to E164 when the factory requires it.

Conclusion

The purpose of the E164 specification is to encourage companies developing EDA/Interface A connections to implement a more common representation of equipment metadata. By following the E164 standard, equipment suppliers and factories can establish greater consistency from equipment to equipment and from factory to factory. That consistency will make it easier and faster for equipment suppliers to provide a consistent EDA interface, and for factories to develop EDA client applications.

Cimetrix held its annual shareholder meeting this past Friday, August 16, 2019 at our headquarters in Salt Lake City, UT. It was nice to see many familiar faces as well as some new faces. There was just one proposal voted on at the meeting to re-elect all five Directors, which was approved by shareholders with over 99% of the votes cast in favor of the proposal. Bob Reback, our President and CEO, introduced each member of Board of Directors and provided a brief history of each board member’s tenure with Cimetrix and the specific expertise and value each of them bring to Cimetrix and our shareholders. We appreciate the wisdom, hard work and direction from our talented board members as well as their commitment to fairly represent the interests of shareholders. We are thankful to our shareholders for their continued support of Management and our Board of Directors.

Cimetrix held its annual shareholder meeting this past Friday, August 16, 2019 at our headquarters in Salt Lake City, UT. It was nice to see many familiar faces as well as some new faces. There was just one proposal voted on at the meeting to re-elect all five Directors, which was approved by shareholders with over 99% of the votes cast in favor of the proposal. Bob Reback, our President and CEO, introduced each member of Board of Directors and provided a brief history of each board member’s tenure with Cimetrix and the specific expertise and value each of them bring to Cimetrix and our shareholders. We appreciate the wisdom, hard work and direction from our talented board members as well as their commitment to fairly represent the interests of shareholders. We are thankful to our shareholders for their continued support of Management and our Board of Directors.

There are some of us in the software development community who recall when cloud computing was not much more than a marketing buzzword, mocked by many developers with first-hand experience at the pace of change in the internet age, but maybe not quite enough experience to know better. Today, cloud-enabled architectures are so commonplace that it’s the alternatives that must be defended in most quarters. Although not necessarily in manufacturing.

There are some of us in the software development community who recall when cloud computing was not much more than a marketing buzzword, mocked by many developers with first-hand experience at the pace of change in the internet age, but maybe not quite enough experience to know better. Today, cloud-enabled architectures are so commonplace that it’s the alternatives that must be defended in most quarters. Although not necessarily in manufacturing. At Cimetrix we have some experience working with manufacturers who are stepping into this area of I4.0 / cloud confluence. Our sense is that the conversations occur along the similar lines of pursuit. The first topics of conversation revolve around fear – security being the chief concern. How can a factory allow its data to leave the four walls? Two recent events have made this argument easier to overcome: TSMC had to shut down a major part of its operations in the summer of 2018 when a computer virus, installed on a new tool, spread to many other hosts. Hundreds of millions of dollars in shipment delays and other costs resulted from a breach of what had previously been thought to be a secure factory environment. On the cloud side: The Capital One breach, where one million social security numbers were stolen, had initial headlines that related it to the Amazon cloud. Since then, the bank has admitted fault and it has become clear that AWS services are secure.

At Cimetrix we have some experience working with manufacturers who are stepping into this area of I4.0 / cloud confluence. Our sense is that the conversations occur along the similar lines of pursuit. The first topics of conversation revolve around fear – security being the chief concern. How can a factory allow its data to leave the four walls? Two recent events have made this argument easier to overcome: TSMC had to shut down a major part of its operations in the summer of 2018 when a computer virus, installed on a new tool, spread to many other hosts. Hundreds of millions of dollars in shipment delays and other costs resulted from a breach of what had previously been thought to be a secure factory environment. On the cloud side: The Capital One breach, where one million social security numbers were stolen, had initial headlines that related it to the Amazon cloud. Since then, the bank has admitted fault and it has become clear that AWS services are secure. Once these fears are assuaged the next line of reasoning tends towards identifying opportunities. This is where Cimetrix is uniquely positioned. We have the expertise to connect factory equipment, get the data into the cloud, and show our customers how to begin exploiting these technologies. Very often the first step is simply to connect as much factory equipment as possible, get a few simple messages, and expand later. This option has proven very fruitful for distributed supply chains that utilize contract manufacturing and outsourcing. Knowing the rate at which equipment is being utilized, which can be done with as few as two simple messages, can be extremely useful. Negotiating capital budgets for new products tends to improve when utilization rates for existing equipment are well known to all parties. The ROI for projects like this tends to be of the scale of months or weeks, not years.

Once these fears are assuaged the next line of reasoning tends towards identifying opportunities. This is where Cimetrix is uniquely positioned. We have the expertise to connect factory equipment, get the data into the cloud, and show our customers how to begin exploiting these technologies. Very often the first step is simply to connect as much factory equipment as possible, get a few simple messages, and expand later. This option has proven very fruitful for distributed supply chains that utilize contract manufacturing and outsourcing. Knowing the rate at which equipment is being utilized, which can be done with as few as two simple messages, can be extremely useful. Negotiating capital budgets for new products tends to improve when utilization rates for existing equipment are well known to all parties. The ROI for projects like this tends to be of the scale of months or weeks, not years.

The Cimetrix Resource Center is a great way to familiarize yourself with standards within the industry as well as find out about new and exciting technologies.

The Cimetrix Resource Center is a great way to familiarize yourself with standards within the industry as well as find out about new and exciting technologies.

The old adage “You get what you pay for” doesn’t fully apply to equipment automation interfaces… more accurately, you get what you require, and then what you pay for!

The old adage “You get what you pay for” doesn’t fully apply to equipment automation interfaces… more accurately, you get what you require, and then what you pay for!

Today is our next edition of the Cimetrix Book Club. Our employees are always striving to develop their skills, share information, and keep up to date with the industry. Part of this effort includes an employee book club that involves many of our team members each month. We will cover some of their favorites from time-to-time here on our blog!

Today is our next edition of the Cimetrix Book Club. Our employees are always striving to develop their skills, share information, and keep up to date with the industry. Part of this effort includes an employee book club that involves many of our team members each month. We will cover some of their favorites from time-to-time here on our blog! This book was designed to be an overview of the programming language, C# and cover the breadth of most topics while delving in depth on some of the topics. It was designed to be helpful for even the most novice developers while still being useful to advanced programmers looking to sharpen their craft. This was perfect for our group because we had a mix of aspiring developers (or developers who hadn’t spent much time programming yet), experienced developers who were new to C#, and experienced developers just looking to get better and learn new things about the language and about best practices.

This book was designed to be an overview of the programming language, C# and cover the breadth of most topics while delving in depth on some of the topics. It was designed to be helpful for even the most novice developers while still being useful to advanced programmers looking to sharpen their craft. This was perfect for our group because we had a mix of aspiring developers (or developers who hadn’t spent much time programming yet), experienced developers who were new to C#, and experienced developers just looking to get better and learn new things about the language and about best practices. We also had two speakers at the Meet-the-Experts tech stage within the Smart Manufacturing Pavilion. Brian Rubow, Director of Solutions Engineering, spoke on how to get the most out of the GEM standard, including following what the standard says and fixing implementations using sound software practices.

We also had two speakers at the Meet-the-Experts tech stage within the Smart Manufacturing Pavilion. Brian Rubow, Director of Solutions Engineering, spoke on how to get the most out of the GEM standard, including following what the standard says and fixing implementations using sound software practices.

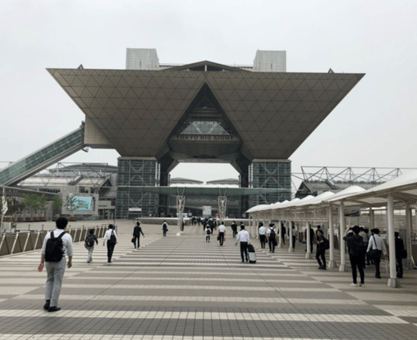

Cimetrix attended the recent JISSO PROTEC exhibition (June 5-7, 2019) at the Tokyo Big Sight International Exhibition Center to see the latest developments in SMT (Surface Mount Technology) manufacturing… and witnessed a truly compelling demonstration of the new SEMI Flow Manufacturing communications standards in action.

Cimetrix attended the recent JISSO PROTEC exhibition (June 5-7, 2019) at the Tokyo Big Sight International Exhibition Center to see the latest developments in SMT (Surface Mount Technology) manufacturing… and witnessed a truly compelling demonstration of the new SEMI Flow Manufacturing communications standards in action. The new suite of standards is named SMT-ELS (Surface Mount Technology-Equipment Link Standards), and includes SEMI A1/1.1 as a lower-level messaging standard with SEMI A2 SMASH (Surface Mount Assembler Smart Hookup) defining the content of the messages required to configure an SMT manufacturing line and automate the material and information transfer among all equipment in that line. This is depicted in the figure below.

The new suite of standards is named SMT-ELS (Surface Mount Technology-Equipment Link Standards), and includes SEMI A1/1.1 as a lower-level messaging standard with SEMI A2 SMASH (Surface Mount Assembler Smart Hookup) defining the content of the messages required to configure an SMT manufacturing line and automate the material and information transfer among all equipment in that line. This is depicted in the figure below.