One of the habits outlined in Stephen R. Covey's book, The 7 Habits of Highly Effective People, is to "Begin with the End in Mind." He goes on to explain that beginning with the end in mind means to "begin each day, task, or project with a clear vision of your desired direction and destination, and then continue by flexing your proactive muscles to make things happen.”

Beginning an equipment control project with a clear vision of your desired destination makes it much more likely that you will have a successful project. A blog post titled CIMControlFramework Work Breakdown dated March 15, 2016 outlined the tasks necessary to create a first-class equipment control application using CIMControlFramework (CCF). Since that initial blog post, Cimetrix has explored each of the tasks labeled in the work breakdown structure in greater depth in their own blog posts as follows:

- Integrate devices – Create Device Drivers Using CCF

- Material movement through the tool – Create a Scheduler Using CCF

- Implement the process module – Implementing Your Process Module Using CCF

- Create an operator interface (OI) – Create Operator Interface Screens Using CCF

- Simulation – Testing Your CCF Application without Waiting for Hardware

- Recipes – Designing Recipes in CCF

- I/O – Using CCF IO Helper Functionality

- Data collection and storage – Storing Data in a CCF Application

- Factory Automation – CCF Provides Fully Implemented GEM300 and EDA Interfaces

- Diagnostics and Testing – This information was provided previously in a two-part blog regarding the benefits of logging. Read Part 1 (Logging - enabling passionate support) and Part 2 (CIMControlFramework Logging Benefits).

- Errors and recovery – CCF provides an Alarms package for signaling of and recovery from error conditions.

Looking back from the successful completion of a CCF equipment control application makes it clear that the work breakdown vision from the beginning helped gain that success.

You can also reference the following blog posts related to CimControlFramework:

CIMControlFramework Dynamic Model Creation

Learning from Others

Build vs. Buy

WCF and CIMControlFramework

To learn more about CCF, visit the CIMControlFramework page on our website!

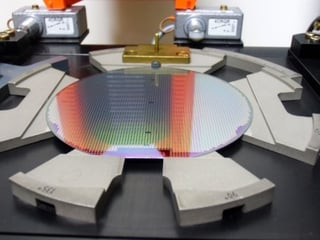

CCF provides a simulator that you can use to test your tool control software during development, and before you run the software on the real hardware. Running against a simulator first will expose issues in your software without damaging people, material and hardware. CCF’s simulator simulates real hardware, which means it is not necessary to add conditional checks in your software to check when it is running with a simulator versus real hardware.

CCF provides a simulator that you can use to test your tool control software during development, and before you run the software on the real hardware. Running against a simulator first will expose issues in your software without damaging people, material and hardware. CCF’s simulator simulates real hardware, which means it is not necessary to add conditional checks in your software to check when it is running with a simulator versus real hardware.